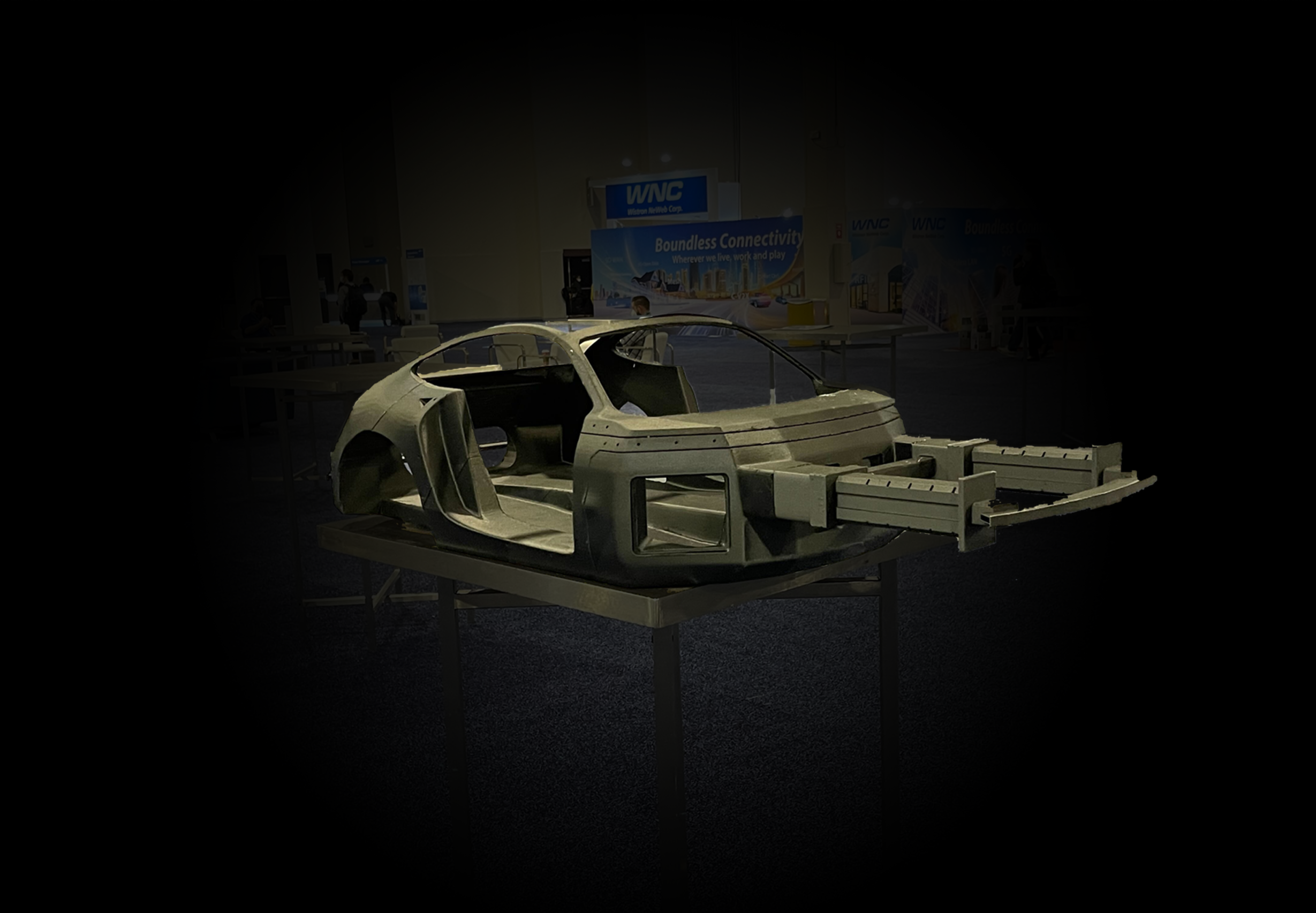

Aerospace-Grade Carbon Fiber. At Automotive Pricing.

At HAZE, we’ve developed a proprietary method for producing large-scale carbon fiber parts through pure automation.

Carbon fiber is one of the most advanced materials on the planet—lighter than aluminum, five times stiffer than steel, and already trusted in Formula 1, aerospace, golf shafts, and elite mountain bikes.

The challenge has always been cost. Traditional production is slow, labor-intensive, and only viable where price is no object.

With our proprietary IP, HAZE makes it possible to deliver aerospace-quality components at automotive pricing. Unlocking carbon fiber’s potential for defense, mobility, and beyond.

Why Clients Choose Us

Performance Without Compromise

- Aerospace-grade strength and stiffness.

- Lighter than aluminum, five times stiffer than steel.

- Trusted by the highest-performance industries.

Cost Redefined

- Proprietary automation slashes labor dependency.

- Unlocks scalability at a fraction of traditional costs.

- Makes carbon fiber viable in markets where price matters.

Scale for the Future

- Capable of producing large-format parts previously impractical.

- Flexible enough to serve aerospace, defense, and mobility.

- Designed for mass adoption, not boutique production.

Backed By

Blog posts

Proprietary Software Stack

Our Proprietary Technology: Enabling Parity with Aluminum

Scaling carbon fiber means getting costs on par with aluminum. We’re not fully there yet. But we’re a lot closer than anyone else. Our breakthroughs in advanced automation, new materials, and AI bring aerospace-quality parts within reach for industries that demand both performance and affordability.

Manufacturing Process

Proprietary Automation

We’ve taken automation principles proven in rocket manufacturing and applied them to larger, more complex carbon fiber parts—delivering consistent quality across challenging geometries and surfaces.

Novel Feedstock

Carbon Fiber derived from Waste

We’ve secured our own carbon fiber supply chain by tapping into abundant waste-derived sources.

Automation AI

Enabling Scalability with Minimal Defects

Our proprietary software stack leverages AI to reduce defects and optimize throughput in scaled-up production.

Frequently Asked Questions

Why is carbon fiber desirable for building large-scale structural parts?

When money is no object, Formula 1 teams choose carbon fiber for their chassis. That’s because it can be engineered to absorb and diffuse massive amounts of energy better than any other material. In fact, race car drivers traveling at speeds over 200 mph can walk away from crashes without a scratch. This is all thanks to carbon fiber’s unique ability to combine lightweight design with extreme impact resistance.

Why hasn’t anyone ever done this before?

Until now, the bottleneck has been manufacturing. Carbon fiber is notoriously labor-intensive, with costs skyrocketing as parts get larger or more complex. At HAZE, our breakthrough lies in combining large-scale automation with software-driven precision. This allows us to achieve aerospace-level accuracy without the traditional weight or cost disadvantages.

Where is your carbon fiber sourced?

We currently work with upcycled carbon fiber sourced locally, ensuring both cost efficiency and sustainability. Our new proprietary feedstock, HD Carbon Fiber, allows us to reach price points unseen in the industry—while maintaining aerospace-grade performance. The core of this material is sourced right here in North America, giving us supply chain security and traceability.

How do I work with you?

It starts with a conversation. Share your CAD files, and our engineering team will collaborate with you on a proof-of-concept—evaluating the right methodologies to scale your part with precision and efficiency. From defense platforms to next-generation mobility, we build with scale in mind from day one.

How close are you really to aluminum pricing?

Aluminum has long been the benchmark for cost and scalability in structural parts. We’re not at full parity yet—but we’re closing the gap faster than anyone else in the industry. By combining proprietary automation, AI-driven defect reduction, and a novel North American feedstock, we’ve already achieved cost structures that make carbon fiber viable in markets where it was previously impossible. Every new generation of our process drives us closer to true aluminum parity, without sacrificing performance.

Press Releases

HAZE Automotive Unveils at CES New Carbon Fiber Frame with AWOS Submersion Sensing Technology

Haze Automotive, Studio 63, and Arcane Four Announce Joint Venture: Ottawa Infotainment